Molasses Based Distilleries Effluent

When nothing is lost everyone gains

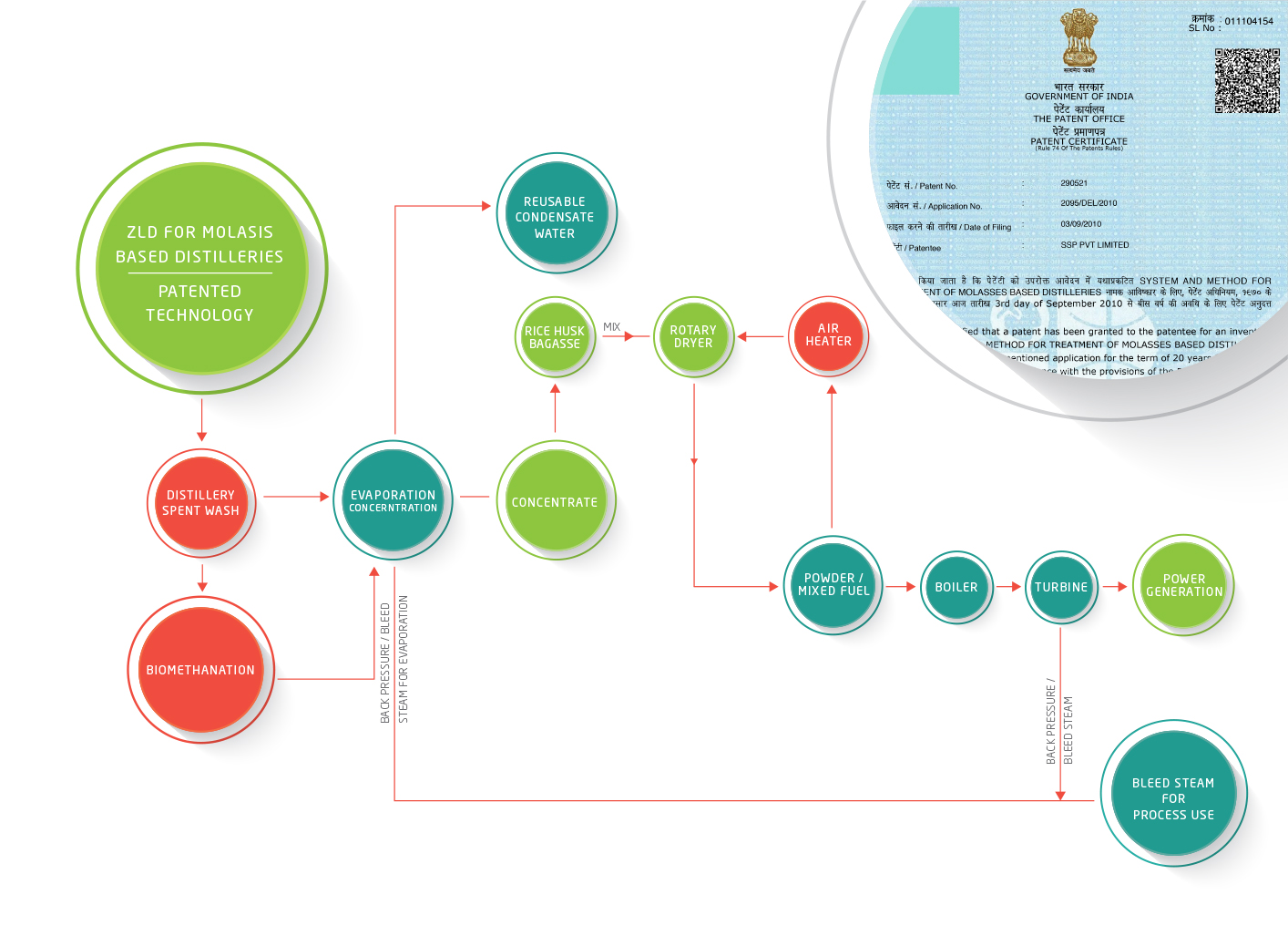

A patented technology from SSP that produces clear and recyclable condensate water from the waste produced in molasses based distilleries.

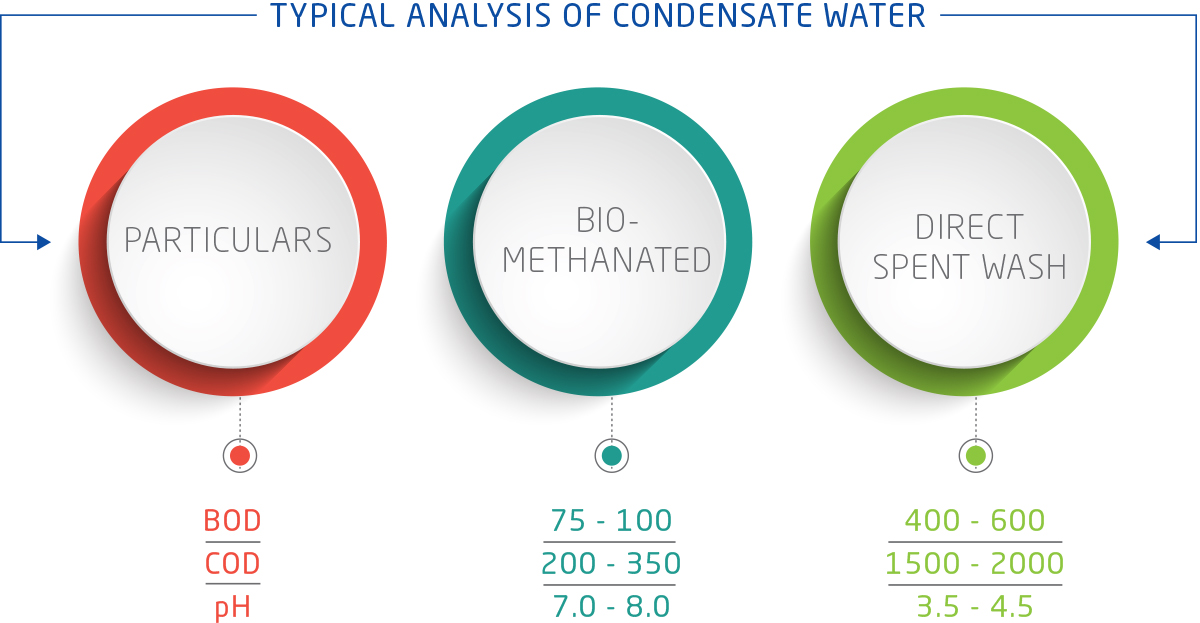

Direct spent wash as well as bio-methanated effluent is concentrated in a multistage vacuum evaporator to 40-60% solids. The total process is under vacuum and the vapors generated in the system are re-compressed in a TVR/MVR to economize steam consumption. Condensate water generated from the evaporation system is clear and recyclable for the process.

In Scheme-A: DIRECT SPENT WASH

The concentrated effluent is mixed with bagasse / rice husk and dried in a Rotary Dryer to generate mixed fuel. This mixed fuel is burnt in a boiler to generate steam and power.

In Scheme-B: BIOMETHANATED EFFLUENT

The concentrated Bio-methenated effluent is dried in a Spray Dryer. The powder generated from spray dryer is mixed with coal and the mixture is burnt in a boiler to generate steam. It can also be marketed as potash rice fertilizer.

High pressure steam is used in a turbine system to generate power. The back pressure / bleed steam can be used in the evaporation system and the generated power is used to operate the evaporation and drying system. Surplus power and steam will be available for distillery operation and other uses.

Typical Analysis of Condensate Water

The concentrated liquor is then mixed with wet cake and dried in rotary dryer to generate DDGS, which has high nutrition value and can be used as cattle feed.